PES Filter Cartridge

Leading PES Filter Cartridge Manufacturer and Supplier for Your Filtration Solution

PES Filter Cartridge

Sterile-Grade Filtration: PES (Polyethersulfone) membrane filter cartridges are ideal for critical applications like pharmaceuticals, biotech, and laboratory filtration.

Hydrophilic Membrane: Our PES filters require no pre-wetting and offer fast wettability, reducing downtime in sterile filtration systems.

Excellent Flow Rate: Designed with uniform pore structure for low pressure drop and high throughput.

Broad Chemical Compatibility: Resistant to a wide range of solvents, making them suitable for complex liquid filtration processes.

Certified Quality: Manufactured in ISO-certified cleanrooms using FDA-compliant materials. Full traceability and documentation available.

Key Features of Our PES Filter Cartridges

High Retention Efficiency: Capable of removing >99.99% of bacteria and fine particulates at 0.2μm and 0.1μm levels.

Hydrophilic PES Membrane: Allows easy wetting without surfactants, improving ease of use in sterile systems.

Low Protein Binding: Ideal for biological and pharmaceutical processes where product loss must be minimized.

Long Service Life: Pleated configuration increases filtration surface area, enhancing dirt-holding capacity.

Fast Flow Rate & Low Pressure Drop: Minimizes energy consumption and improves process throughput.

Thermally Bonded Construction: No adhesives, binders, or glues – ensuring high purity and compatibility.

Gamma Sterilizable & Autoclavable: Suitable for CIP/SIP operations in GMP environments.

Compliance Ready: Manufactured under ISO 9001/13485 systems, FDA-approved raw materials, and full documentation.

High-Efficiency Filtration Solutions for Power Generation

Filter Cartridges in Petroleum and Chemical Industries

Microelectronics Industry

Water Treatment Industry

Aplications of Our PES Filter Cartridges

PES pleated filter cartridges are specially designed for applications requiring absolute cleanliness, sterility, and high flow performance. Key industries and uses include:

Pharmaceutical Manufacturing: Final filtration of injectable drugs, eye drops, IV fluids.

Biotechnology: Sterile filtration of media, buffers, cell cultures.

Medical Devices: Liquid filtration for diagnostic reagents and rinsing fluids.

Laboratories: Sterile filtration of biological samples and culture media.

Food & Beverage: Microbiological control in bottled water, wine, and beer.

Microelectronics: Pre-filtering ultrapure water and chemicals.

Their ability to retain microorganisms while allowing high flow makes PES filters the standard choice in sensitive and regulated applications.

Learn More About >> Applications of PES Pleated Filter Cartridges.

Specification of PES Filter Cartridge

| Parameter | Specification |

|---|---|

| Filter Media | Hydrophilic Polyethersulfone (PES) |

| Support Layers | Polypropylene (PP) |

| Micron Ratings | 0.1μm, 0.2μm, 0.45μm, 0.65μm |

| Lengths | 10”, 20”, 30”, 40” |

| Outer Diameter | 68mm / 69mm / 115mm |

| End Cap Options | DOE, 222/Flat, 222/Fin, 226/Flat, 226/Fin |

| Core/Cage | Polypropylene (thermally bonded) |

| Operating Temperature | Up to 85°C (185°F) |

| Max Differential Pressure | 4.2 bar at 25°C; 2.1 bar at 80°C |

| Sterilization Methods | Gamma irradiation, Steam (121°C for 30 mins) |

| Extractables | ≤30mg/10” (per USP <661> in WFI) |

| Certifications | ISO 9001, ISO 13485, FDA, CE, SGS |

How to Choose the Right Pleated Filter Cartridge – Industrial Filtration Selection Guide

PES Pleated Filter Cartridge Catalogue

Our Quality Control for PES Filter Cartridge Manufacturing

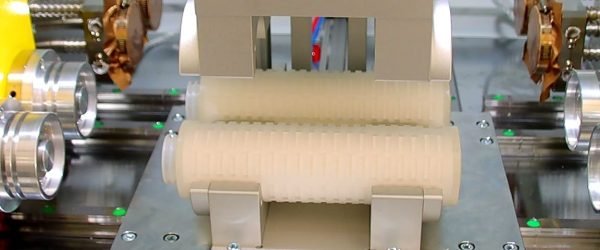

Our membrane filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Why Choose Us as Your PES Filter Cartridge Supplier

As a professional PES filter cartridge manufacturer and supplier in China, we focus on providing high-quality filtration solutions that meet the demanding requirements of global industries. Here’s why hundreds of clients choose us as their long-term partner:

1. Factory-Direct Supply

We control the full production process – from membrane casting to final assembly – within our ISO-certified facility. This ensures strict quality control, fast lead times, and competitive prices.

2. Sterile Production Environment

Our PES cartridges are produced in class 100,000 cleanrooms and tested under GMP-compliant protocols. Every filter undergoes integrity testing and traceable batch coding.

3. Strong R&D Support

We continuously develop new filtration solutions tailored to customer requirements. Whether you need high throughput or specific chemical compatibility, our engineering team is ready to assist.

4. OEM & Private Label Available

We offer custom packaging, labeling, and design services for distributors and system integrators. Build your own brand with our high-performance filters.

5. Global Export Experience

With customers in over 60 countries, we understand international compliance and logistics. From small orders to container loads, we offer reliable and flexible shipping options.

Choosing us means you get more than just a product – you get a filtration partner dedicated to your success.

Frequently Asked Questions (FAQ)

What is PES Filter Cartridge

A PES filter cartridge is a pleated filtration element made from hydrophilic polyethersulfone (PES) membrane, designed for high-purity liquid filtration. PES membrane filters are widely recognized for their high flow rates, low protein binding, and excellent microbial retention efficiency.

These cartridges are engineered to remove bacteria, particles, and other impurities from fluids in sensitive applications such as pharmaceuticals, laboratory processes, food & beverage production, and medical device manufacturing. Unlike PTFE or PVDF membranes, PES filters do not require pre-wetting, which enhances operational efficiency and cost savings.

The pleated design increases surface area, extending filter life and reducing frequency of replacement. They are typically used as final-stage filters in critical liquid processing systems, especially where sterility and consistency are essential.

Available in various micron ratings such as 0.1μm, 0.2μm, and 0.45μm, PES filter cartridges are compatible with most industry-standard housings, including 222 and 226 end caps. Whether for small lab systems or industrial-scale sterile production, PES pleated filters provide reliable and repeatable performance.

What’s the difference between PES and PVDF membrane filters?

PES (Polyethersulfone) membranes are hydrophilic and have lower protein binding than PVDF, making them ideal for biological and pharmaceutical applications. PVDF is more hydrophobic and used in aggressive chemical environments.

Are PES filter cartridges reusable?

PES filters are primarily designed for single-use sterile filtration. Some applications may allow cleaning and reuse, but filtration efficiency may decline after repeated sterilization.

How can I verify filter integrity?

We provide bubble point and diffusion test data for each batch. Integrity test kits are available upon request, or we can provide on-site support for validation.

Can I get customized micron ratings or lengths?

Yes. While 0.2μm and 0.45μm are standard, we can produce other ratings upon request. Lengths like 5”, 10”, and 20” can be customized to fit your housing.

Do PES cartridges comply with FDA and USP standards?

Absolutely. All materials are FDA-compliant and tested according to USP Class VI, <85>, <87>, <88> for biocompatibility and extractables.

What’s the MOQ and lead time?

We provide bubble point and diffusion test data for each batch. Integrity test kits are available upon request, or we can provide on-site support for validation.

Contact Us

Looking for a trusted PES filter cartridge manufacturer in China? Get in touch with our expert team for free consultation, fast quotation, and custom filter solutions.