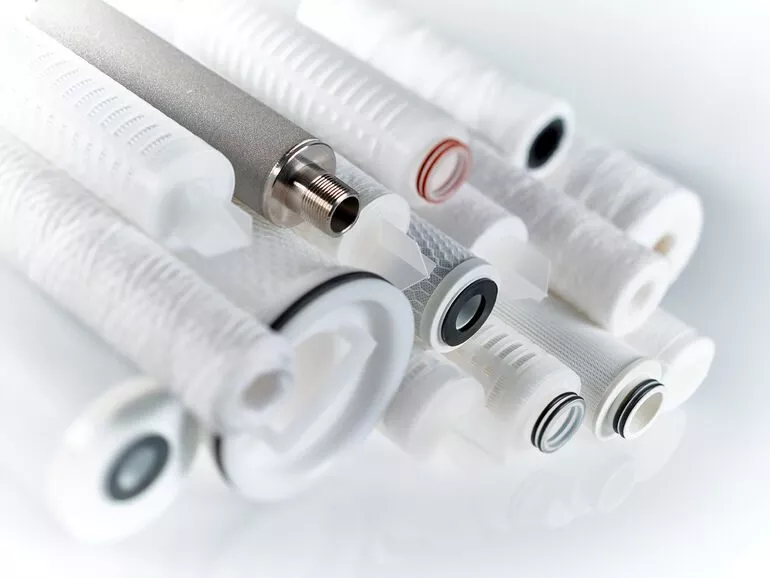

How to Choose the Right Pleated Filter Cartridge – The Ultimate Industrial Filtration Selection Guide

INTRODUCTION

Why Choosing the Right Pleated Filter Cartridge Matters

In industrial filtration, selecting the right pleated filter cartridge is not just a purchasing decision — it is an engineering decision that directly affects system reliability, operating cost, product quality, and regulatory compliance.

A poorly selected cartridge can cause:

Excessive pressure drop and energy loss

Frequent clogging and premature replacement

Contamination of final products

Damage to downstream membranes, pumps, and equipment

On the other hand, a correctly engineered pleated filter cartridge provides:

Stable filtration efficiency

Long service life

Low operating cost

Consistent and compliant process performance

Unlike simple strainers or bag filters, pleated filter cartridges are designed as high-efficiency precision filtration elements. Their pleated structure dramatically increases effective surface area, allowing high flow rates and excellent particle retention in a compact form.

This guide explains, step by step, how to select the right pleated filter cartridge for your specific filtration system — based on fluid type, contaminant characteristics, flow rate, micron rating, chemical compatibility, membrane type, and connection design.

2. Understand Your Filtration Application First

Before selecting any filter cartridge, the most important step is to understand what you are filtering and why.

2.1 What Fluid Are You Filtering?

Different fluids impose very different demands on filter media.

| Fluid Type | Typical Challenges |

|---|---|

| Water | Particulates, bacteria, organic matter |

| Chemicals | Corrosiveness, solvent attack |

| Pharmaceuticals | Sterility, regulatory compliance |

| Food & Beverage | Hygiene, taste, odor, safety |

| Solvents | Hydrophobic compatibility |

| Gases | Venting, moisture, particle control |

For example, a cartridge suitable for potable water may fail rapidly in a solvent filtration system.

2.2 What Contaminants Must Be Removed?

The contaminant type determines the micron rating and filter media structure.

Common contaminants include:

Suspended solids (sand, rust, scale)

Colloidal particles

Microorganisms

Oil and emulsions

Gels and organic matter

Rigid particles are easily captured by surface filtration, while deformable contaminants may require depth or gradient filtration.

2.3 Where Is the Filter Installed in the Process?

Filtration stage matters:

| Process Stage | Purpose |

|---|---|

| Pretreatment | Protect downstream equipment |

| Intermediate | Reduce load on final filters |

| Final filtration | Protect product quality |

| Sterile filtration | Remove microorganisms |

Pleated filter cartridges are most often used for fine filtration and final filtration, where precision and cleanliness matter.

3. How to Choose the Right Membrane Material

The filter membrane is the heart of a pleated cartridge. Selecting the correct membrane material is one of the most important decisions.

3.1 Common Pleated Filter Media

| Material | Key Characteristics | Typical Applications |

|---|---|---|

| Polypropylene (PP) | Chemical resistant, economical | Water, chemicals |

| Polyethersulfone (PES) | High flow, low protein binding | Pharmaceuticals |

| Polyvinylidene Fluoride (PVDF) | Strong chemical resistance | Aggressive chemicals |

| Polytetrafluoroethylene (PTFE) | Extremely hydrophobic | Solvents, gas |

| Nylon | Broad chemical compatibility | Organic solvents |

3.2 PP vs PES vs PVDF vs PTFE vs Nylon

Each material offers a unique balance of chemical resistance, hydrophilicity, mechanical strength, and filtration efficiency.

PP Pleated Filter Cartridges are widely used for water treatment and general chemicals due to low cost and good chemical resistance.

PES Membrane Filter Cartridges provide very high flow rates and are ideal for pharmaceutical and biopharmaceutical filtration.

PVDF Membrane Filter Cartridges offer excellent resistance to oxidizing agents and harsh chemicals.

PTFE Membrane Filter Cartridges are preferred for air, gas, and aggressive solvent filtration.

Nylon Membrane Filter Cartridges provide balanced solvent compatibility and good mechanical strength.

3.3 Chemical and Thermal Resistance

Some membranes degrade when exposed to high temperature, acids, or solvents.

| Membrane | Acid | Solvent | Temperature |

|---|---|---|---|

| PP | Good | Limited | Up to ~80°C |

| PES | Moderate | Limited | ~80–120°C |

| PVDF | Excellent | Good | ~130°C |

| PTFE | Excellent | Excellent | ~200°C |

| Nylon | Good | Good | ~100°C |

Using the wrong material may result in swelling, cracking, or complete filter failure.

Learn More>> How to Choose the Best Filter Cartridge Material for Systems

4. Hydrophilic or Hydrophobic – Which Should You Choose?

4.1 What Is a Hydrophilic Membrane?

Hydrophilic membranes attract water and allow water to pass through easily.

They are used for water-based filtration.

Examples: PP, PES, PVDF (hydrophilic treated)

4.2 What Is a Hydrophobic Membrane?

Hydrophobic membranes repel water and are used for:

Air filtration

Gas venting

Solvent filtration

PTFE is the most common hydrophobic membrane.

4.3 Application-Based Selection

| Application | Membrane Type |

|---|---|

| Drinking water | Hydrophilic |

| Pharmaceutical liquids | Hydrophilic |

| Compressed air | Hydrophobic |

| Chemical solvents | Hydrophobic |

| Fermentation venting | Hydrophobic |

Using the wrong type can cause air lock, flow blockage, or wetting failure.

Difference Between Hydrophilic Filter vs Hydrophobic Filters

5. How to Choose the Correct Micron Rating

5.1 Nominal vs Absolute Rating

Nominal micron rating means the filter captures a percentage (usually 85–95%) of particles at that size.

Absolute micron rating means the filter captures ≥99.9% of particles at that size.

For critical filtration, absolute-rated pleated cartridges are required.

5.2 Typical Micron Ranges

| Application | Micron |

|---|---|

| Pretreatment | 5–20 µm |

| RO protection | 1–5 µm |

| Fine filtration | 0.45–1 µm |

| Sterile filtration | 0.1–0.22 µm |

Selecting too fine a micron increases pressure drop and cost.

Selecting too coarse allows contamination to pass through.

6. How to Calculate Required Flow Rate

Flow rate is controlled by:

Filter surface area

Pleat density

Membrane permeability

Differential pressure

Pleated cartridges provide much higher flow than depth cartridges due to large surface area.

If your system requires 10 m³/h, the filter must provide that flow at acceptable pressure drop, not just at zero pressure.

How to Select Cartridge Filter Flow Rate for Filtration Need

7. Pressure Drop and Dirt Holding Capacity

Pressure drop increases as contaminants accumulate.

A good pleated filter cartridge provides:

Low initial pressure drop

High dirt holding capacity

Stable filtration over time

This results in fewer replacements and lower operating cost.

8. Chemical Compatibility

Never assume a membrane is chemically resistant.

Acids, alkalis, solvents, and oxidizers can:

Attack filter fibers

Damage O-rings

Cause extractables

Always match membrane and seal materials to the process fluid.

9. How to Select the Correct Cartridge Dimensions

Selecting the right membrane and micron rating is meaningless if the cartridge does not physically fit into your filtration housing.

9.1 Standard Lengths

Pleated filter cartridges are typically available in:

10 inch

20 inch

30 inch

40 inch

Longer cartridges provide greater surface area and higher flow capacity.

For high-flow systems, 40” cartridges are often preferred to reduce the number of cartridges required per housing.

9.2 Diameter and Effective Filtration Area

Although many cartridges share similar external diameters, their pleat count and pleat depth determine the actual filtration area.

A high-quality pleated filter cartridge with optimized pleat geometry provides:

Higher flow rate

Lower pressure drop

Longer service life

This is especially important for PVDF and PTFE membranes, which are typically used in high-value applications where downtime is costly.

10. How to Choose the Right End Cap and Connection Type

The end connection determines how the cartridge seals inside the housing and how well it prevents bypass.

10.1 DOE (Double Open End)

Both ends are open

Sealing is achieved by flat gaskets

Low cost

More risk of bypass

DOE cartridges are commonly used for PP pleated filters in water and pretreatment systems.

10.2 SOE (Single Open End)

SOE cartridges provide positive sealing using O-rings or bayonet-style locking mechanisms.

Common SOE types:

| Code | Description |

|---|---|

| Code 3 | Double O-ring, flat top |

| Code 7 | Bayonet, high sealing |

| Code 8 | Single O-ring, common in pharma |

For PVDF and PES pharmaceutical filters, Code 7 and Code 8 connections are standard because they eliminate leakage risk.

10.3 Why Connection Type Matters

A poorly sealed cartridge allows unfiltered fluid to bypass the membrane, making even a 0.2 µm filter useless.

For critical filtration — pharmaceutical, food, microelectronics — always use SOE sealed cartridges.

11. O-Ring and Seal Material Selection

The membrane filters the fluid — the O-ring keeps it from leaking around the membrane.

| O-Ring Material | Best For |

|---|---|

| EPDM | Water, steam |

| Silicone | Food & pharma |

| Viton (FKM) | Chemicals & solvents |

| PTFE | Extreme chemical resistance |

For PTFE and PVDF pleated filter cartridges used in aggressive chemical service, Viton or PTFE O-rings are typically required.

12. Integrity Testing – How to Verify Filter Performance

High-quality pleated filter cartridges are not only manufactured — they are tested.

12.1 Why Integrity Testing Matters

Integrity tests ensure that:

The membrane has no pinholes

Pleats are intact

End caps are sealed correctly

This is especially critical for 0.2 µm pharmaceutical-grade PES and PVDF filters.

12.2 Bubble Point Test

The bubble point test measures the pressure at which air passes through a wetted membrane.

A higher bubble point means:

Smaller pore size

Higher filtration efficiency

Why Filters Cartridge Require Bubble Point Integrity Test and Its Importance

12.3 Diffusion Test

This measures the gas flow rate through a wetted membrane at a given pressure.

It is commonly used for on-site integrity testing in pharmaceutical plants.

12.4 Water Intrusion Test

Used for hydrophobic PTFE membranes, especially for vent filters.

13. Regulatory and Industry Standards

13.1 FDA Compliance

Filters used in food, beverage, and pharmaceutical applications must use FDA-compliant materials.

13.2 USP Class VI

This is required for filters in direct contact with pharmaceutical products.

13.3 ISO and GMP

High-quality pleated filter cartridge manufacturers operate under:

ISO 13485 (medical)

GMP production

These standards ensure consistency, traceability, and product reliability.

14. Common Mistakes When Selecting Pleated Filter Cartridges

14.1 Choosing Micron Rating Too Small

This leads to:

High pressure drop

Rapid clogging

High operating cost

14.2 Ignoring Chemical Compatibility

Using a PP cartridge in solvent service or an EPDM O-ring in acid is a common failure mode.

14.3 Using DOE for Critical Filtration

This often causes bypass leakage.

14.4 Buying on Price Alone

Low-cost cartridges often use:

Low pleat density

Inferior membranes

Poor sealing

This increases long-term cost.

15. How to Optimize Performance and Cost

Professional filtration systems often use multi-stage filtration:

Depth filter or melt blown filter

PP pleated pre-filter

PVDF, PES, or PTFE final filter

This protects the expensive final membrane and extends its life.

16. Final Selection Checklist

Before ordering any pleated filter cartridge, confirm:

Fluid type

Chemical compatibility

Required micron rating

Flow rate and pressure

Membrane material (PP / PES / PVDF / PTFE)

Hydrophilic or hydrophobic

Length and diameter

End cap type

O-ring material

Regulatory requirements

17. How to Match the Right Product to Your Application

Based on this guide:

PP Pleated Filter Cartridges

Best for water treatment, RO pretreatment, and general industrial filtration.PVDF Pleated Filter Cartridges

Ideal for chemical processing, pharmaceutical filtration, and aggressive fluids.PTFE Pleated Filter Cartridges

Best for solvents, compressed air, and vent filtration.

By selecting the correct membrane, connection type, and testing standard, your filtration system will operate with maximum efficiency, safety, and reliability.