PVDF Filter Cartridge

High Quality PVDF Filter Cartridge Manufacturer & Supplier with Wholesales Price

PVDF Filter Cartridge

Excellent Chemical Resistance: PVDF filter cartridges provide outstanding resistance to acids, bases, solvents, and oxidants—ideal for harsh chemical environments.

Hydrophilic & Hydrophobic Options: Suitable for both aqueous and non-aqueous fluid filtration in biotechnology, semiconductor, and chemical industries.

High Flow & Low Pressure Drop: Pleated design with uniform pore structure ensures efficient throughput and minimal pressure loss.

Thermal Stability: Operates at high temperatures up to 130°C, making it suitable for SIP and autoclave sterilization.

FDA-Approved & ISO Certified: Made with FDA-compliant PVDF materials in ISO-class cleanrooms. Full traceability and testing documentation provided.

What is PVDF Filter Cartridge

A PVDF filter cartridge is a pleated membrane filter made from polyvinylidene fluoride (PVDF), a high-performance thermoplastic fluoropolymer. It is renowned for its broad chemical compatibility, mechanical strength, and thermal resistance. PVDF filter cartridges are widely used in liquid and gas filtration applications where aggressive media and high temperatures are involved.

These filters are available in both hydrophilic and hydrophobic variants, allowing them to be used for water-based or solvent-based solutions. PVDF’s low protein binding and extractables make it suitable for critical applications in pharmaceuticals, food & beverage, laboratory, and electronics manufacturing.

Unlike conventional filters, PVDF cartridges maintain excellent flow rates while offering long service life due to their pleated structure and robust media. They are compatible with most standard filter housings and are available in various lengths, micron ratings, and end cap configurations.

PVDF membrane filters are often chosen as final-stage filters in processes that demand high-purity, stability, and sterility. Their versatility, durability, and high efficiency make them a premium choice in demanding environments.

Key Features of Our PVDF Pleated Filter Cartridges

Broad Chemical Compatibility: Resists acids, bases, oxidizers, and organic solvents. Ideal for harsh chemical filtration.

Hydrophilic & Hydrophobic Options: Enables flexibility in filtering both aqueous and non-aqueous liquids or gases.

High Temperature Resistance: Operates up to 130°C, suitable for steam sterilization and hot chemical processes.

Low Extractables: Ensures ultra-pure filtration for sensitive applications like pharmaceuticals and electronics.

Low Protein Binding: Prevents sample loss and ensures efficiency in biological and pharmaceutical processes.

Pleated Structure: Maximizes filtration surface area for high flow rates and extended filter life.

Sterilizable & Reusable: Can withstand multiple steam or gamma sterilization cycles.

Standard Compatibility: Available in DOE, 222, 226 end caps and fits most common filter housings.

These features make PVDF pleated filter cartridges a highly reliable choice for demanding fluid or gas filtration processes.

Ordering Information

| MF | -PT | -0022 | -10 | -P | -H | -1 | -S |

| Model | Media | Micron | Length | Inner Core | Surface | End Cap | O-Ring |

| MF | PV= PVDF | 0010= 0.10um 0022= 0.22um 0045= 0.45um 0100= 1.0um 0500= 5.0um | 05= 5 Inch 10= 10 Inch 20= 20 Inch 30= 30 Inch 40= 40 Inch | P= PP S= SUS304 U= SUS316 V= PVDF | H= Hard PP N= Mesh S= SUS304 U= SUS316 V= PVDF | 0= DOE 1= 222Flat 2= 222Fin 3= 226Flat 4= 226Fin | S= Silicone F= FKM E= EPDM T= PTFE K= FEP-FKM |

Specification of PTFE Filter Cartridge

Outer Diameter68mm / 64mm/ 62mm

| Parameter | Specification |

|---|---|

| Filter Media | Polyvinylidene Fluoride (PVDF) |

| Membrane Layers | Single Layer, Double Layers, Muti-layers for Option |

| Operating Temperature | Up to 120°C (248°F) |

| Max Differential Pressure | 4.0 bar @ 25°C, 2.5 bar @ 80°C |

| Sterilization | Steam (121°C for 30 mins), Gamma irradiation |

| Extractables | ≤30mg per 10″ cartridge (in accordance with USP <661>) |

| Typical Applications | Solvents, acids, WFI, ultrapure water, gas filtration |

How to Choose the Right Pleated Filter Cartridge – Filter Selection Guide

High-Efficiency Filtration Solutions for Power Generation

Filter Cartridges in Petroleum and Chemical Industries

Microelectronics Industry

Water Treatment Industry

Applications of Our PVDF Filter Cartridges

PVDF filter cartridges are ideal for applications that demand chemical resistance, thermal stability, and filtration precision. Common industries and uses include:

Pharmaceuticals: Filtration of solvents, injectables, and water-for-injection (WFI).

Microelectronics: Final filtration of ultrapure water (UPW) and chemicals in semiconductor fabs.

Chemical Processing: Resistant to aggressive acids and solvents in chemical manufacturing.

Food & Beverage: Used in wine, beer, and syrup filtration where low extractables are required.

Laboratories & Research: High-purity filtration of buffer solutions, DNA/RNA samples, and reagents.

Medical Device Production: Sterile filtration in implantable and diagnostic product manufacturing.

With their hydrophilic and hydrophobic options, PVDF membrane filters serve a broad range of critical filtration needs.

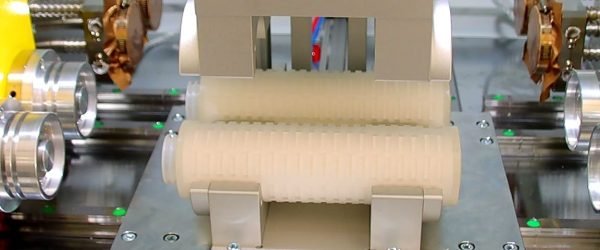

Our Quality Control for PVDF Filter Cartridge Manufacturing

Our membrane filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Why Choose Us as Your PVDF Filter Cartridge Manufacturer

As a professional PVDF filter cartridge manufacturer and supplier in China, we specialize in delivering precision filtration solutions tailored to the needs of various high-end industries.

Strict Quality Control

Strict Quality Control

Our manufacturing facility operates under ISO 9001 and ISO 13485 standards. Every PVDF filter cartridge is manufactured in a class 100,000 cleanroom, integrity tested, and fully traceable.

Custom OEM Solutions

Custom OEM Solutions

We provide OEM and private labeling options to global distributors and system integrators. Custom micron ratings, end cap types, gasket materials, and branding are all available.

Competitive Pricing & Global Logistics

Competitive Pricing & Global Logistics

As a direct factory, we eliminate middlemen and offer factory-direct pricing. We ship to over 50 countries and support fast delivery via air and sea.

Technical Support & Documentation

Technical Support & Documentation

Our engineers can help with application analysis, filter validation, and regulatory documentation, including FDA, CE, and USP Class VI compliance.

Full Range of Products

Full Range of Products

Beyond PVDF, we also manufacture PES, PTFE, Nylon, and PP pleated filter cartridges, allowing one-stop sourcing for all your filtration needs.

With years of experience and a commitment to quality, we are your trusted PVDF pleated filter cartridge supplier in China.

Learn More>> Pleated Filter Cartridge Selection Guide: Size, Media & Performance

Frequently Asked Questions (FAQ)

Q1: What is the difference between hydrophilic and hydrophobic PVDF filters?

A1: Hydrophilic PVDF filters are pre-treated to allow wetting with water-based solutions, ideal for aqueous filtration. Hydrophobic PVDF is naturally water-repellent and is used for gas or solvent filtration.

Q2: Can PVDF cartridges be sterilized and reused?

A2: Yes. PVDF filters are steam sterilizable and gamma resistant, making them suitable for multiple cycles in pharmaceutical and biotech environments.

Q3: What is the shelf life of a PVDF filter cartridge?

A3: Unused PVDF filters typically have a shelf life of 3–5 years if stored in a cool, dry, and clean environment in their original packaging.

Q4: How do I know if PVDF is the right filter material for my application?

A4: PVDF is ideal for processes involving aggressive chemicals, solvents, or high-purity water. If your application involves extreme pH, temperature, or requires low extractables, PVDF is highly suitable.

Q5: Can I order PVDF cartridges in custom sizes or packaging?

A5: Absolutely. We provide custom sizing, labeling, and packaging services. Whether you’re a distributor or system OEM, we can tailor products to meet your brand requirements.

Our Replacement Solutions

Contact Us

Looking for a trusted PVDF filter cartridge manufacturer in China? We offer high-quality membrane filtration products, competitive pricing, and global OEM support.

Strict Quality Control

Strict Quality Control